As with most cab over trucks fitted with a bullbar, it is necessary to tilt the bullbar prior to tilting the cab. Failing to tilt the bullbar first will likely result in damage to the cab. I have first hand knowledge of this… I forgot and ended up with a $300 repair bill.

Sure, there is normally a warning sticker near the cab release handle but, if like me you get distracted, forgetting to tilt the bullbar will likely be a costly mistake. I also found other people that had done exactly the same thing; so I am not alone when it comes to making stupid mistakes.

So, not wanting to make the same blunder twice, I started looking at what I could do to “idiot proof” the cab tilt mechanism.

The solution seemed quite straight forward; design an electrical circuit that would sense when the cabin release lever had been opened and determine if the bullbar was tilted forward or not. If the bullbar was not tilted, sound an alarm.

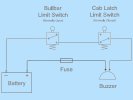

The circuit is very simple, only requiring two limit switches and a buzzer.

On the bullbar there needs to be a normally open (NO) switch and on the cab release mechanism there needs to be a normally closed (NC) switch. This means that when the bullbar is up the circuit is closed and when tilted the circuit is open. Adversely, when the cab release leaver is latched the circuit is open and when unlatched the circuit is closed.

If the the circuit is closed, which can only happen when the cab release lever is unlatched and the bullbar is not tilted, the buzzer sounds.

I could have wired the circuit with positive running through the switches but, given that most of the truck’s components are negatively switched, it seemed logical to keep this circuit similar to the rest of the truck.

The only real challenge here was finding suitable limit switches.

Given that the switches would potentially be exposed to the elements, they needed to be reasonably resistant to water and dust.

I determined that an IP67 rating would be the best choice for this job, so the search begun to find some suitable switches…

As is often the case, finding stuff can be harder than installing it. After many hours spent scouring the internet, I ended up sourcing my switches directly from a factory in China. These switches were 90% cheaper than anything I could find in Australia, which is really sad.

The switch for the bullbar is mounted directly to the steel bullbar mounting bracket. I drilled and tapped two M4 holes in the mount to secure the switch. The cab release lever switch is mounted in the driver’s side latching assembly. To fit this switch I removed the latching assembly from the truck to get the correct positioning. This switch is also secured with M4 bolts, screwed directly into the latch assembly.

I ran 3mm twin core sheathed cable (1.13 mm²) inside 10mm split conduit through the hollow structural rail that runs under the cab in order to get it to the front. The cables from both switches were run into the inside of the cab through an existing cable grommet behind the driver’s side headlight. One wire from each cable was joined together, heatshrink was put over the joint and the remaining pair of wires were then fitted to a female two pin connector. Another length of twin core cable was fitted with a male connector and this was run up under the dash to the other side of the cab where one wire was connected to earth and the other to the negative side of the buzzer wire. Another cable connector was used here too. The positive wire runs through a fuse block and then directly to the buzzer, completing the circuit.

A 95dB piezo buzzer (from Jaycar) is mounted in the rear quarter panel cavity, behind the passenger’s inertia real seat belt. I had thought about mounting the buzzer on the outside of the truck, but it was much simpler fitting it inside the cab; and I did not need to use a waterproof buzzer.

Given that the position of the buzzer is very close to where the cabin release handle is located, hearing the buzzer from the outside is not an issue at all.

Now it should be virtually impossible to raise the cab before the bullbar has been tilted. Well, that’s the theory…

Click any image to enlarge

Click any image to enlarge